Portland Stone Cement and Pulhamite

William Lockwood joined his uncle's building company in Woodbridge in 1802. They were agents for a new type of cement which was made by Parker & Wyatt from the mid 1790s. The cement was called Roman because it was claimed to be equal to the cement made by the Romans and, in some applications, superior to it. The cement was waterproof and was thus suitable for cladding the outside of buildings. Although the cement was light brown it could be colour washed to make it appear like stone.

To demonstrate the attributes of the concrete made using Roman cement William built a new house for his family in 1812 and completely clad its walls and flat roof with concrete. The surrounds of windows and doors were made of concrete. The addition of battlements and a turret in one corner resulted in the building becoming known as The Castle. The concrete roof proved to be a step too far. Although the concrete was a barrier to water it cracked because of movement of the underlying roof timbers and eventually slate had to be used instead.

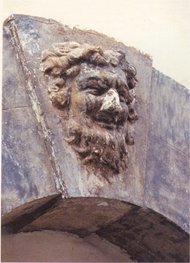

The cladding of buildings in concrete became a significant part of Lockwood's work. The addition of decorative features on the front of buildings was also becoming fashionable and Lockwood started to use concrete to made porticos and entablatures to decorate doorways and to make decorative key stones. These decorative features were cast in concrete using moulds made by the brothers James and Obadiah Pulham. James had not received any formal education but he made up for this by attending evening classes and as soon as his apprenticeship was finished he was appointed foreman of Lockwood's thirty strong workforce.

The colour wash used to make the surface of concrete look like stone was not very durable and William realized his business would be more successful if he could create a concrete which looked like Portland stone. To that end, in 1817, he toured the country to find the most suitable form of limestone for his purpose. He eventually found what he wanted in South Wales and had it shipped from Swansea to the Lime Kiln Quay at Woodbridge. It was then carted up Sun Lane to his newly created cement mill where he started to produce his ‘Portland Stone Cement’.

Lockwood soon had teams of men cladding buildings and adding moulded decorative features to houses far from Woodbridge. Sometime between 1819 and 1822 he opened an office at Spitalfields and James Pulham was installed as manager and his brother was made his assistant.

The Pulhams were kept busy producing the moulds for ornamental work such as porticos as well as entablatures, pediments and other features of classical architecture then in vogue. They were also producing moulds for garden vases, fountains, chimney pots, coats of arms and animal figures.

In 1834 William Sr. closed his branch at Tottenham and returned to Woodbridge where he and his son Alfred, who had had some training as an architect in London, continued their business as builders. It seems likely that they left because of the competition from other builders who, by then had access to cement, which was as good as, or better, than his.

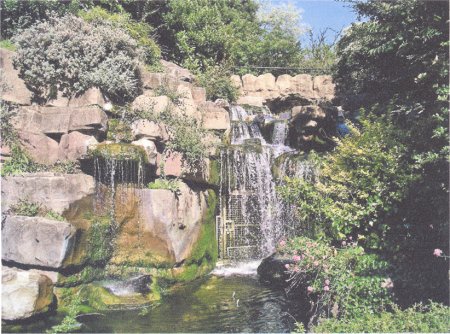

The Pulhams remained at Tottenham and proceeded to build up their own business for decorative cement work. Within four years James died and his eldest son, another James, who was only eighteen years old at the time, took over the business. He was eventually joined by his son, James II, who expanded the scope of the business. James II achieved a national reputation because of his ability to use cement to create artificial rock formations. Soon a number of influential clients asked him to create artificial rocks in the gardens which he landscaped for them.

The artificial rocks, which were eventually called ‘Pulhamite’, were made by assembling a mass of clinker and other discarded building materials to form the rough shape, and then coating it with Lockwood’s Portland Stone Cement. There are many examples of the Pulhamite around the country. The most prestigious being at Sandringham, Windsor Castle and Buckingham Palace.

James II was as skilled as his father in making moulds and in mid 1840s he moved to Broxbourne in Hertfordshire where he created a workshop to produce ornate garden ornaments in artificial stone. The inspiration for the designs and shapes of their vases was mostly contemporary; a Victorian mixture of Classical and Gothic, and the work of famous sculptors provided patterns for figures on fountains.

Pulham was not the only manufacturer of artificial stone ornaments - the eighteenth and nineteenth centuries saw a marked increase in the number of manufacturers, Mrs Coade, Blashfield and Doulton being the most well-known. There were an increasing number of wealthy industrialists and others all over the country with money to spend on beautifying their gardens and artificial stone was considerably cheaper than marble or real stone.

James II died in 1898 at his home in Tottenham but he was buried in Broxbourne churchyard. Some three years earlier the firm had been granted the Royal Warrant for work carried out at Sandringham and later at Windsor Castle and Buckingham Palace. By this time the firm was in the hands of his son, James III and his grandson, James IV.

In 1912 Pulham and Sons built a rock garden of natural Sussex sandstone into a north-facing hillside at the RHS Garden at Wisley. Some modifications and improvements have taken place since but it is still a most striking feature of the gardens

James III retired, and died in 1920, and the fortunes of the firm declined steadily after that until trading ceased during the early years of the Second World War. The staff needed to look after huge gardens did not exist anymore and years of austerity spelled the end of lavish expense on horticultural fashions.

The concrete clad house which Lockwood built for his family in Woodbridge. Because of the turrets and castellation it became known as The Castle .

A cement key stone and door way which were moulded in Woodbridge.

Most of the seafront of Ramsgate is lined by Pulhamite cliffs, and Pulhamite features such as this waterfall and pond.

.

A fountain made by James II in his factory at Broxbourne.